Results

Solution

The business challenge

Reducing dependency on physical labor through automation

The business challenge

A large global supplier of high-performance fibers to the personal protective equipment (PPE) manufacturing market had found that elements in its production processes were placing a heavy physical strain on employees – and this was having an impact on the organization’s ability to retain staff working in its facilities.

It wanted to explore whether increased automation could improve the ergonomic arrangements in these working environments and decrease the company’s dependence on physical labor. At the same time, it wanted to see if automated solutions could help to optimize its production processes and deliver cost efficiencies.

The company developed an initial automation program which it hoped would increase output by 13% and reduce costs by 30%. We were then asked to help it find ways to accelerate the roll out and execute the integration of the technology within its operations.

The solution

The first step was for us to assess the proposed automation initiative, within context of the company’s wider Industry 4.0 roadmap. This evaluation enabled our team to challenge the approach and its scope – for example, could it be extended to the finishing process and packaging?

The next step was for us to support the deployment of the technology and the accompanying change management program. This helped the organization adapt its processes and develop new maintenance methodology. To ensure the success of the deployment, our team involved operators in the implementation phase, providing education and training around the new ways of working.

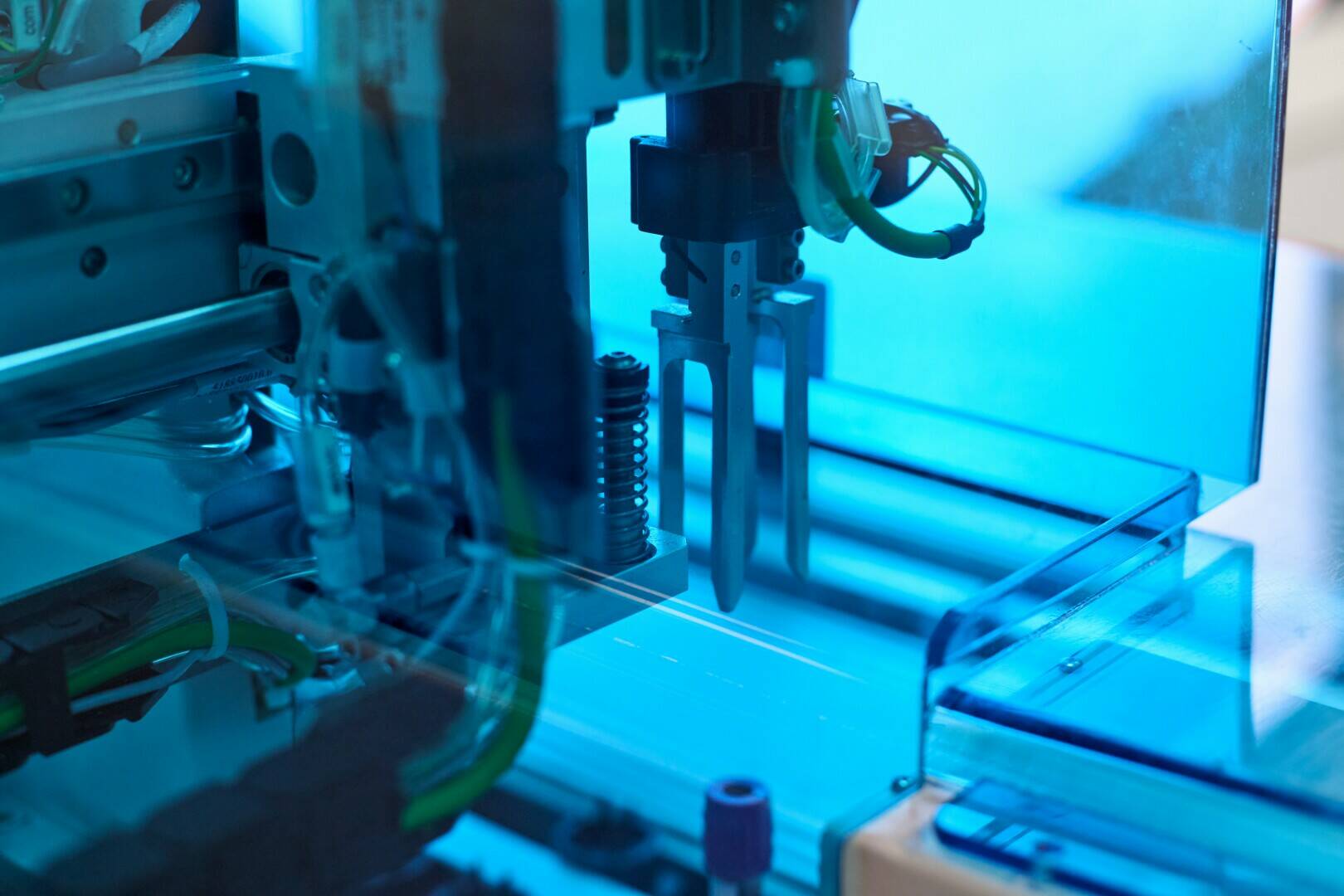

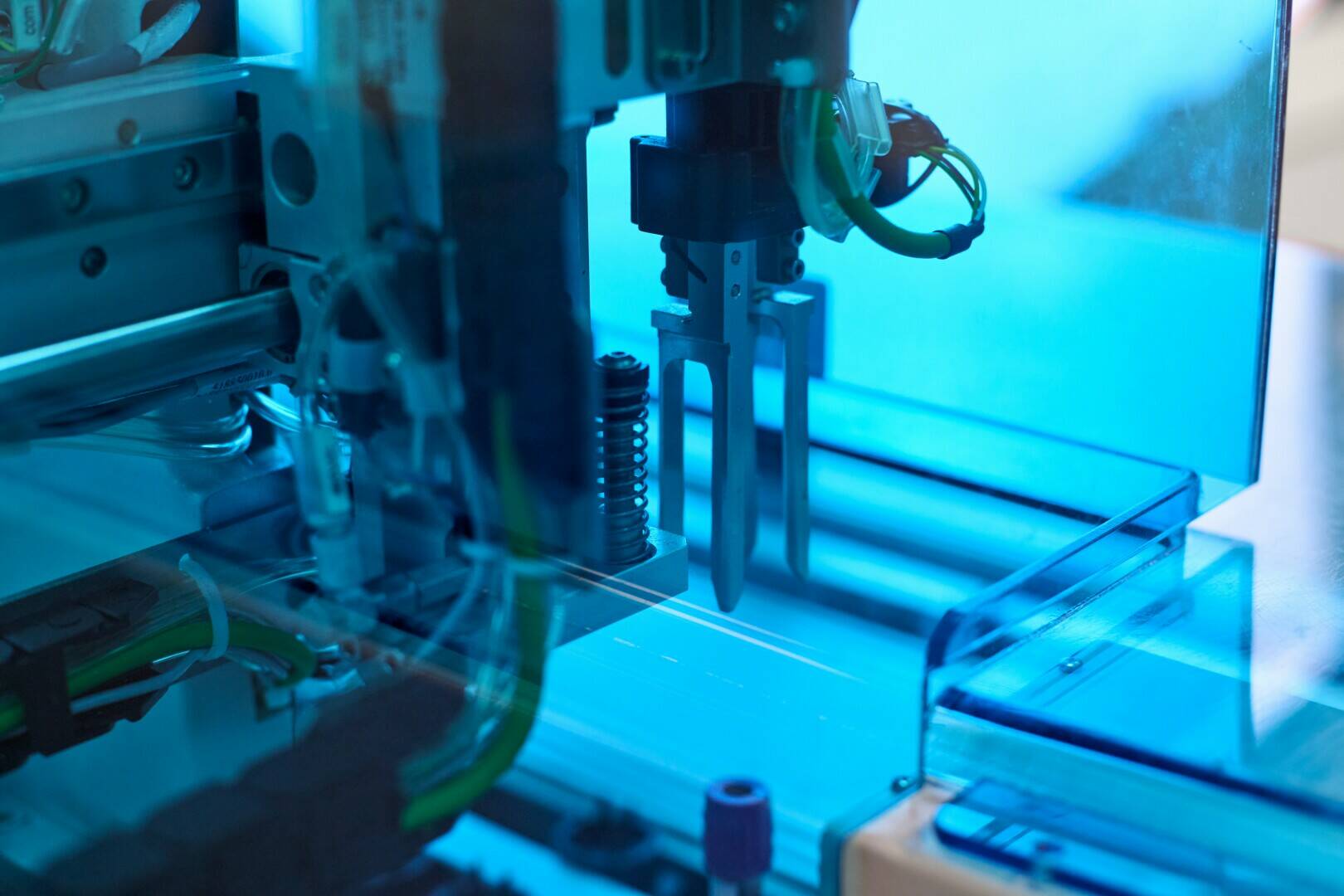

Following our team’s initial assessment, we also presented the business case for additional automation solutions to be deployed, which was subsequently approved. This included the adoption of collaborative robots (cobots) in the packaging process, including the installation of robotic arms, and automated guided vehicles (AGV) as a replacement for forklift trucks in warehouse environments.

We delivered support throughout this second phase of automation, which included technology selection, implementation, and process adaptation.

Results

The deployment of automated technology has enabled the company to reduce the physical strain being placed on employees – creating a working environment that is more operator friendly. This is now helping the organization attract, and, importantly, retain employees.

The business has also been able to improve the predictability and quality of its processes, and increase output as a result. The introduction of cobots and AGVs has helped to reduce the number of operators required on shift by 75%. This has provided the company with annual cost savings valued at more than €1m.

24 months

Project duration

Asia

Location

High-performance fibers

Industry

The deployment of automated technology has enabled the company to reduce the physical strain being placed on employees – creating a working environment that is more operator friendly. This is now helping the organization attract, and, importantly, retain employees.

The business has also been able to improve the predictability and quality of its processes, and increase output as a result. The introduction of cobots and AGVs has helped to reduce the number of operators required on shift by 75%. This has provided the company with annual cost savings valued at more than €1m.

Results

The first step was for us to assess the proposed automation initiative, within context of the company’s wider Industry 4.0 roadmap. This evaluation enabled our team to challenge the approach and its scope – for example, could it be extended to the finishing process and packaging?

The next step was for us to support the deployment of the technology and the accompanying change management program. This helped the organization adapt its processes and develop new maintenance methodology. To ensure the success of the deployment, our team involved operators in the implementation phase, providing education and training around the new ways of working.

Following our team’s initial assessment, we also presented the business case for additional automation solutions to be deployed, which was subsequently approved. This included the adoption of collaborative robots (cobots) in the packaging process, including the installation of robotic arms, and automated guided vehicles (AGV) as a replacement for forklift trucks in warehouse environments.

We delivered support throughout this second phase of automation, which included technology selection, implementation, and process adaptation.

The solution

The business challenge

24 months

Project duration

Asia

Location

High-performance fibers

Industry

A large global supplier of high-performance fibers to the personal protective equipment (PPE) manufacturing market had found that elements in its production processes were placing a heavy physical strain on employees – and this was having an impact on the organization’s ability to retain staff working in its facilities.

It wanted to explore whether increased automation could improve the ergonomic arrangements in these working environments and decrease the company’s dependence on physical labor. At the same time, it wanted to see if automated solutions could help to optimize its production processes and deliver cost efficiencies.

The company developed an initial automation program which it hoped would increase output by 13% and reduce costs by 30%. We were then asked to help it find ways to accelerate the roll out and execute the integration of the technology within its operations.

Reducing dependency on physical labor through automation